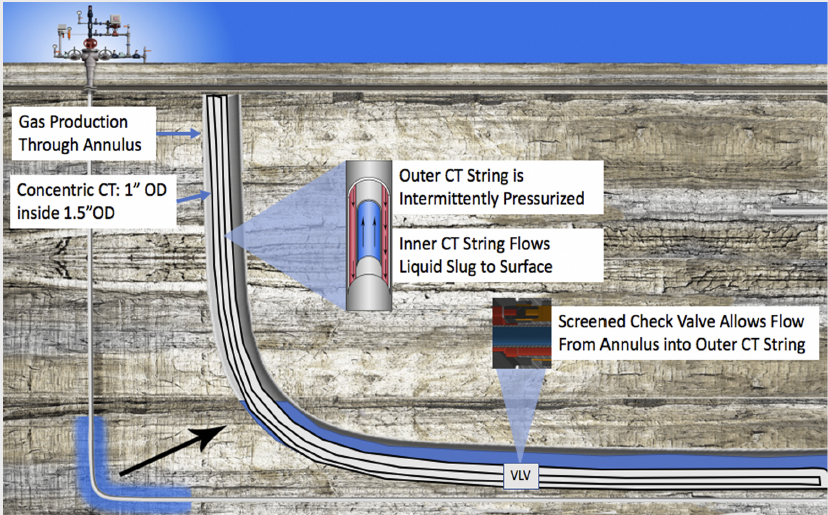

WHAT IS GALLOP?

• GALLOP – Gas Assisted Liquid Lift using Oscillating Pressure

• A dual tubing system with check valve(s) that can lift liquids from multiple points in a horizontal well bore without putting lift pressure on the formation

WELL SELECTION CRITERIA

• Target liquid rates less than 50 BLPD

• Access to lift gas at pressures suitable for GALLOP*

• Low solids production, low chance for future frac interference

• Uplift potential if well could be “pumped off”

• A Sucker-Rod pump below the perfs in a vertical

• Existing tubing preferred

HOW TO SPOT A LOADING PROBLEM?

• Well is approaching min-lift rates anywhere in the wellbore

• High frequency data shows surging or cycling gas rates

• Decreasing (or zero) surface liquid yield (liquids are being left downhole)

FOUR STAGES PER CYCLE

• FILL – Liquids in sump(s) fill horizontal section(s) of Dual Tubing (DT), check it open

• GAS INJECTION – Pressurized gas is injected into one side of DT, check closes

• LIQUID PRODUCTION – Lift gas drives liquid slug to surface, check closed

• BLOW DOWN – DT pressure is relieved to flowline, check re-opens

MORE BENEFITS

• GALLOP can defer P&A on problem wells

• Ability to monitor performance in real time as cycle times are tuned

• Keeps reserves on the books

• Production pays for the system costs

TECHNICAL SPECIFICATIONS

• Total Length – 68”

• OD – 4 3/8”

• Effecitive screen size – 4” Dia x 48” L

• Sand Screen 100 micron

• System Volume Flow Rate 3gpm

• Added Centralizers

PATENT INFORMATION

GALLOP Protected under US Patent 8794305B2 & 9435163B2