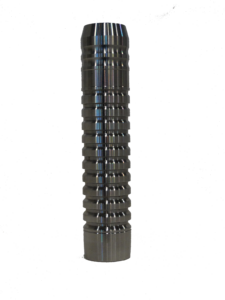

The Padded Talon is equipped with innovative technologies to maintain fast fall speed and increase production through Well Master’s Mechanical Seal Technology.

APPLICATIONS

Used in wells that are in the initial stage of liquid loading which produce high gas and liquid volumes, and are showing signs of struggling with the produced liquid volume compared to traditional sleeves.

FEATURES AND BENEFITS

• Flow/Shift Pad Technology is specifically designed for exceptional sealing properties in fast falling well applications

• Aerodynamic Vents allow the sleeve to fall against more flow and achieve more trips/day to produce more oil and gas

• Reliability through Dual Surface Seal on the ball and sleeve interface

• Longevity is achieved by proprietary advanced metallurgy and surface treatment

• Multiple ball materials available

• TALON RF & TALON TS versions are available for applications that require falling against more flow