WHAT IS THE PROBLEM BEING ADDRESSED?

The traditional approach to understanding desired plunger velocity is based on operating within the “ideal” target range. However, the problem is, the control systems only measure the average velocity fringe the start of the rise cycle to the end. Plunger velocity can actually vary enormously from bottom to top of the well.

WHEN SHOULD ADVANCED FLOW CONTROL (AFC) BE USED?

• Where good plunger velocity management is key for best plunger operating efficiency and production

• Where broken plungers and/or damage to surface equipment is prevalent

• Low line pressure or high variable line pressure environments

• Large differences in flowing gas velocity from bottom to top of the well

BENEFITS

• SAFETY: Minimize fast arrivals

• EQUIPMENT INTEGRITY: Fewer broken plungers and damaged surface equipment

• INCREASE PLUNGER LIFE: Excess speed wears plungers faster. Controlled speeds extend plunger life

• INCREASE PLUNGER EFFICIENCY: Narrow the velocity range over the entire trip

• SPEEDS: recovery from pressure upset conditions as wells line out automatically

• REDUCES: operator intervention for plunger replacement and wellhead issues

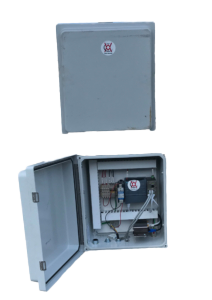

WHAT IS ADVANCED FLOW CONTROL (AFC) COMPATIBLE WITH?

• RTU Controllers w/ MODBUS

• Conventional and cloud-based SCAD

AFC is a proprietary technology from Well Master

*Patent Pending