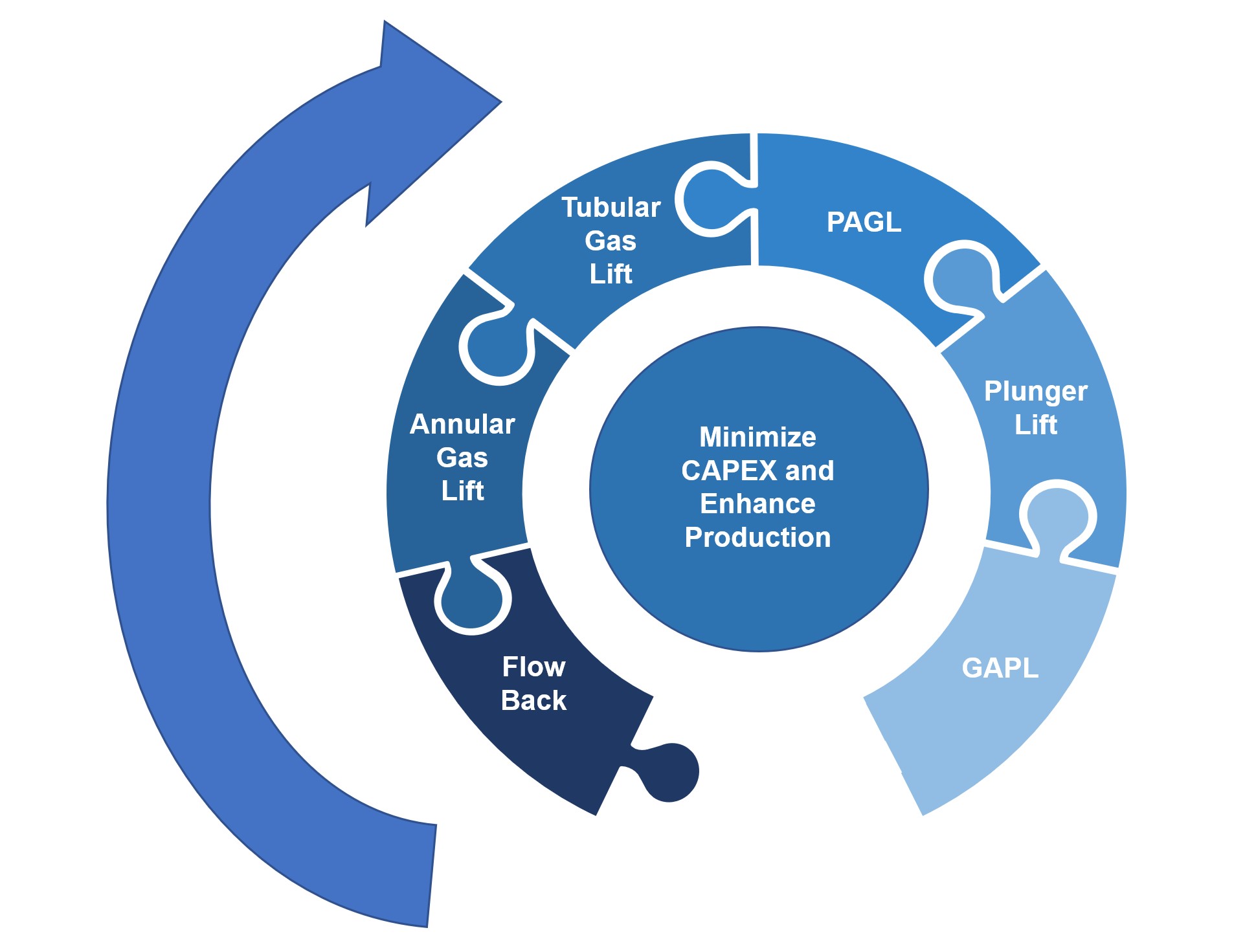

Many people use these terms interchangeably to refer to combinations of gas-lift and plunger-lift. While we know of no formal SPE definition, we use GAPL to refer to gas-assisted plunger-lift, and PAGL to refer to plunger-assisted gas-lift. With this perspective, PAGL and GAPL can come at two distinctly different times in the life cycle of the well.

In each case one form of lift is assisting another primary form of lift:

PAGL: The plunger assists and extends the economic life of the gas-lift system by improving the efficiency and economics at lower rates. The amount of time that a gas lift system can operate towards the end of the life cycle, before switching to another form of lift, can be extended.

GAPL: The gas injection assists and extends the economic life of the plunger-lift system by supplementing the reservoir drive. The amount of time that a plunger-lift system can operate towards the end of the life cycle, before switching to another form of lift, can be extended.

Another way to imagine the difference from an applications standpoint in the majority of cases is:

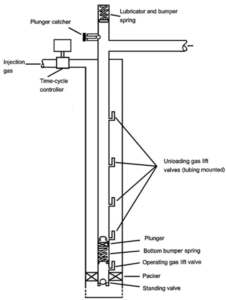

- PAGL: Continuous gas-lift, assisted by a continuous-run plunger.

- GAPL: Plunger-lift assisted by continuous or intermittent gas injection.

While the proper application of PAGL and GAPL can both bring improvements to production over one form of lift alone, they are also distinct forms of lift that can be planned for in the life-cycle of the well. By designing the well to anticipate the changes and minimize the workover costs, production and economic efficiency can be optimized.

Is your gas lift installation in need of a performance boost at lower rates?

As the economic efficiency of a gas lift system declines, often an investment is required to switch to an entirely different form of artificial lift. In many cases, combining a plunger with gas lift can extend the economic life span of a gas lift system.

What can PAGL do for me?

The plunger not only helps to sweep liquid fallback to the surface and reduce BHP, but it effectively improves the ability of the gas to move the liquid so that injection rates can be reduced, and the effect of slippage can be minimized.

Even in a gas-lifted well that is fully optimized, the addition of a plunger can reduce injection rates by 25 to 40% and improve liquid rates by 10 to 30%.

This changes the economic viability of a gas lift system at lower rates and can delay the capital expense of moving to another form of artificial lift.

Plungers also bring the proven benefit of helping to clean up scale and paraffin issues. The plunger can be set as deep as 60 degrees for optimum BHP management.

How do I know if my well is a candidate for PAGL?

We use nodal analysis to predict when a plunger may improve well performance, but some of the key signs are:

- Liquid rates below 450 BPD

- Production is becoming unstable and starting to surge or head

- On multi-well pad sites where injection rate capacity is needed by other wells

- Scale or paraffin buildup is impacting production

What can GAPL do for me?

If you are looking to extend the production and life-cycle of your plunger-lift system, then Gas Assisted Plunger Lift may be a valuable option. At lower reservoir pressures and rates – GAPL is the application of intermittent gas lift to assist a plunger lift system.

GAPL can be applied when the formation drive is below the requirement to operate a plunger system independently, or when improved plunger performance can be created by utilizing gas compression.

Key points like “when should a horizontal well be shut in after the plunger arrives?” is critical to the production results and overall success.

Planning ahead and using a “life of well strategy” can make significant savings and simple transitions from Gas lift/PAGL/GAPL/Plunger lift successful throughout the life of the well.